Robot grinding

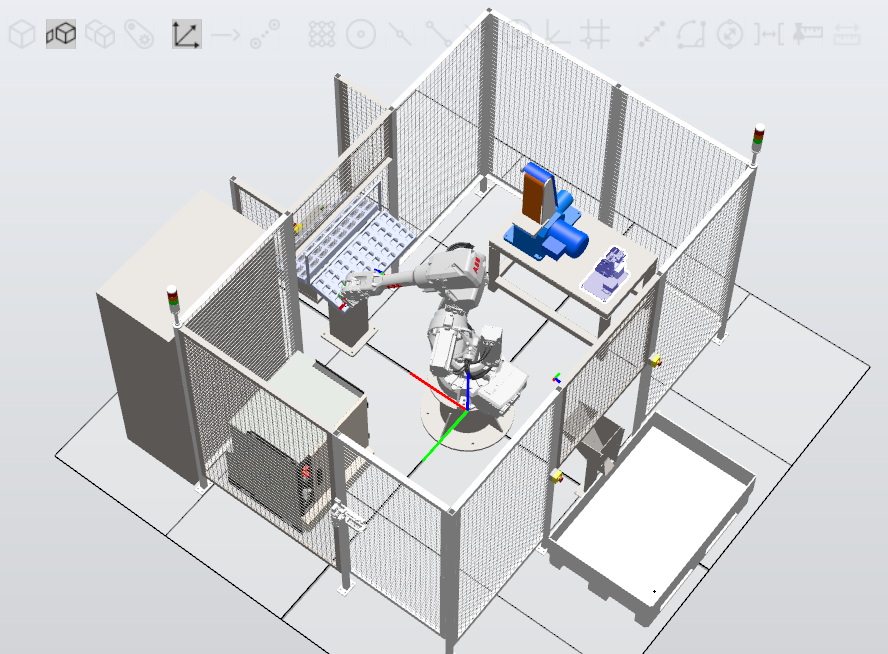

Automated grinding cell

We offer design and installation of automatic grinding cells. First, the baseline is analysed and key KPIs are set, followed by a preliminary cost-benefit analysis. For a promising project, the expected payback period is 1-3 years. Our expertise includes:

-Mapping the existing process and defining KPIs. Mapping the material flow. Analysis of cycle times.

-Development of technical solutions, including feed mechanisms, gripping of parts, selection of grinding machine, selection of robot.

-Production cell simulation with real cycle times.

-Design and manufacture of machinery and equipment.

-Risk assessment and CE conformity.

-Installation and integration to the production line.

-Maintenance and programming.

Contact us, to start automating your factory!

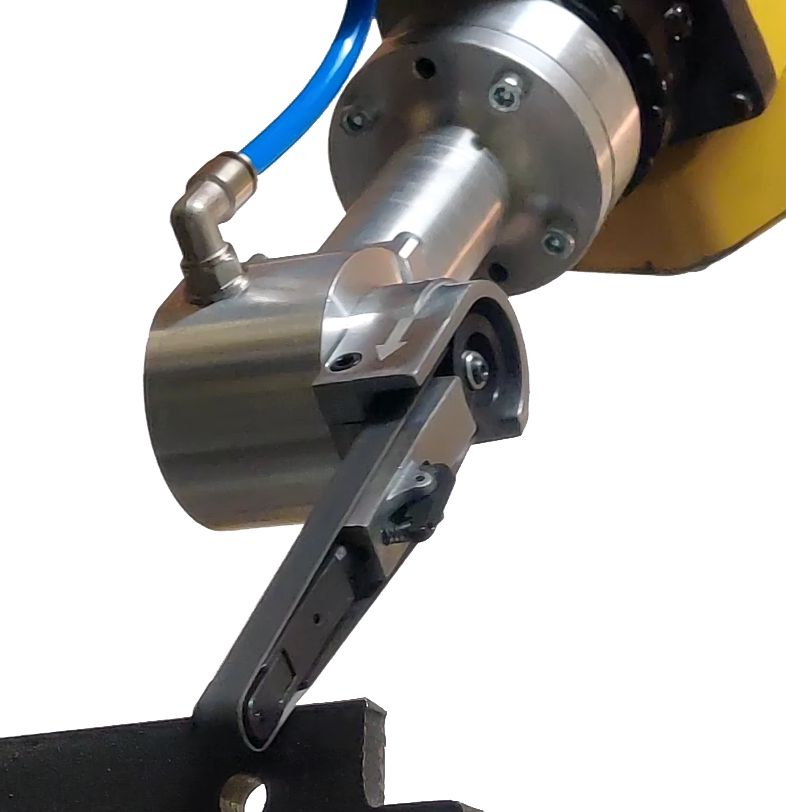

Pneumatic grinder for robot 10x330

Pneumatic grinding machine for industrial and collaborative robots.

Suitable for grinding, deburring and edge rounding of various parts.

-Adjustable working head.

-Pressure 0,6 Mpa

-Pneumatic connection NPT 1/4, flange ISO 9409-63mm

-Max. speed 20 000 rpm

-Required air flow rate 200 l/min

-Made in Estonia

We supply high quality abrasive belts for different materials (metal, wood, glass, etc.).

Possibility to produce a flange that fits your robot. If required, we can assist with the integration to the robot system.

We also offer design and manufacture of special tooling according to the customer's requirements.

Servo turntable for robot

The servo turntable is suitable for the robot to feed the parts. It can also be used as an additional axis for machining complex parts. Different types of jigs can be placed on the table.

-High quality Mitsubishi servo motor, programmable according to the task.

-Positioning accuracy +- 0,01mm.

-Board diameter 300mm, maximum load 30kg.

-Interfacing with the robot via I/O signals or Databus.

-Reliability ensured, the machine will stop in the event of overload or other failure.

-Rigid machined steel construction

Can be produced in different sizes and according to the customer's requirements. We can help to interface the turntable to your robot system.

Universal grinding gripper for robot

Universal grinding gripper for smaller parts. The gripper jaws are machined according to the shape of the workpiece. The Z-axis pneumatic compensator ensures uniform grinding force and repeatable results.

-Axis ISO 9409-63mm

-Schunk pneumo haarats

-Schunk Z-axis compensator, pressure adjustable

-Special gripper packs according to the detail